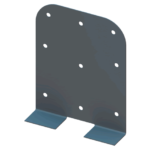

Kwik-Back (KB) products are the most cost effective and labor saving solution for creating superior backing support for wall shelving, cabinetry, heavy wall hangings, and other equipment.

Installation is simplified by using three screws and attaching the clip to the stud flange. No predetermined stud layout is required and ledge tabs are added for easy alignment. Attach 2″ x 6″ structure grade lumber (#1 or better) as required by codes or specifications.

Features

- Pre-punched guide holes

- Folded tabs for consistent wood positioning

Material Composition

- ASTM A653/A653M

- Material thickness: 33 mil

- Yield strength: 33 ksi

- G60 hot-dipped galvanized coating

Gallery

Allowable Loads

| Stud Thickness | Yield Strength (ksi) |

Allowable Loads (lbs) | ||||

|---|---|---|---|---|---|---|

| Mils | Gauge | F1 (3) Screws | F3 (3) Screws | |||

| #8 | #10 | #8 | #10 | |||

| 27 | 22 | 33 | 177 | 177 | 363 | 363 |

| 30 | 20 | 33 | 195 | 228 | 423 | 453 |

| 33 | 20 | 33 | 216 | 252 | 492 | 531 |

| 43 | 18 | 33 | 282 | 327 | 732 | 789 |

Screw shear values are based on the SSMA Screw Table with the following notes:

- The allowable loads are based on the steel properties of the members being connected, per NASPEC with 2004 supplements.

- The nominal strength of the screw must be at least 3.75 times the allowable loads.

- Values include a 3.0 factor of safety.

- Penetration of screws through joined materials should not be less than three exposed threads. Screws should be installed and tightened in accordance with the screw manufacturer’s recommendations.

- Allowable loads indicated on the table(s) are for force in single direction only. If more than one force is applied to the connection, the designer shall provide the combined forces check as required by NASPEC with 2004 supplements.

Quantity / Order Information

| Model No. | Flange Width | Qty /Bucket |

Lbs /Bucket |

|---|---|---|---|

| KB162 | 1-1/4” to 1-5/8” | 100 | 25 |

| KB200 | 2″ | 100 | 27 |