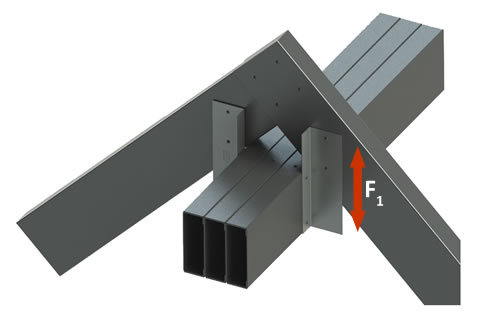

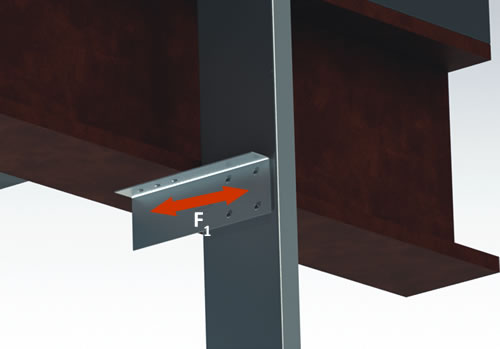

The load-bearing secure strut (AS) is used in various applications, but most commonly to connect an exterior wall stud that bypasses the building structure through the use of a 90° angle strut. The AS is designed to resist compression loads and axial tension. It may be attached to the structure with either an approved fastener or a weld, depending on the material properties of the structure and the proposed design.

Features

- Available in a variety of different lengths for all requirements and construction tolerances

- Replaces the expensive traditional method of bracing

- Used in a variety of different applications

- Produced from thicker steel to improve welded attachments

- Manufactured from mill-certified 57 ksi steel

Material Composition

- ASTM A653/A653M

- Material thickness: 68 mil

- Yield strength: 57 ksi

- G90 galvanized coating

Allowable Loads

| Model No. | Stud Thickness | Yield Strength (ksi) |

Allowable Loads (lbs) | ||||

|---|---|---|---|---|---|---|---|

| Mils | Gauge | F1 2 #10 Screws |

F1 4 #10 Screws |

F1 6 #10 Screws |

F1 8 #10 Screws |

||

| AS | 33 | 20 | 33 | 354 | 708 | 1068 | 1416 |

| 43 | 18 | 33 | 526 | 1052 | 1578 | 2104 | |

| 54 | 16 | 50 | 740 | 1480 | 2220 | 2960 | |

| 68 | 14 | 50 | 1046 | 2092 | 3138 | 4184 | |

| 97 | 12 | 50 | 1046 | 2092 | 3138 | 4184 | |

Screw shear values are based on the SSMA Screw Table with the following notes:

- The allowable loads are based on the steel properties of the members being connected, per NASPEC with 2004 supplements.

- The nominal strength of the screw must be at least 3.75 times the allowable loads.

- Values include a 3.0 factor of safety.

- Penetration of screws through joined materials should not be less than 3 exposed threads. Screws should be installed and tightened in accordance with the screw manufacturer’s recommendations.

- Allowable loads indicated on the table(s) are for force in single direction only. If more than one force is applied to the connection, the designer shall provide the combined forces check as required by NASPEC with 2004 supplements.

- It is the responsibility of the designer to check the bending in the short leg of this clip.

Quantity / Order Information

| Model No. | Width | Qty /Bucket |

Lbs /Bucket |

Buckets /Skid |

Lbs /Skid |

|---|---|---|---|---|---|

| AS800 | 8” | 75 | 53 | 40 | 2160 |

| AS1000 | 10” | 50 | 45 | 40 | 1840 |

| AS1200 | 12” | 50 | 55 | 40 | 2240 |

| AS1500 | 15” | 35 | 48 | 40 | 1960 |

| AS2000 | 20” | – | – | – | – |

| AS2400 | 24” | – | – | – | – |